-

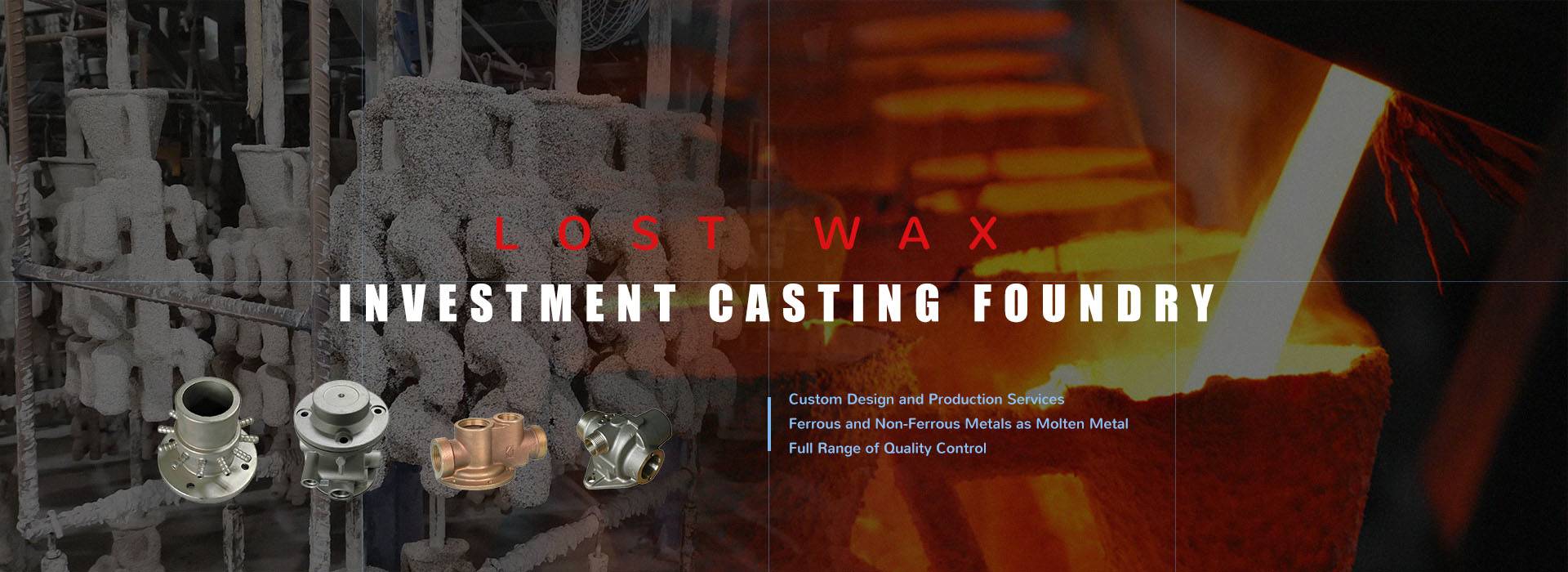

Investment Casting

A lost wax investment casting foundry which pour stainless steel, carbon steel, alloy steel, gray cast iron, ductile cast iron, aluminium alloy, nickel alloys, cobalt alloys, brass and bronze.more -

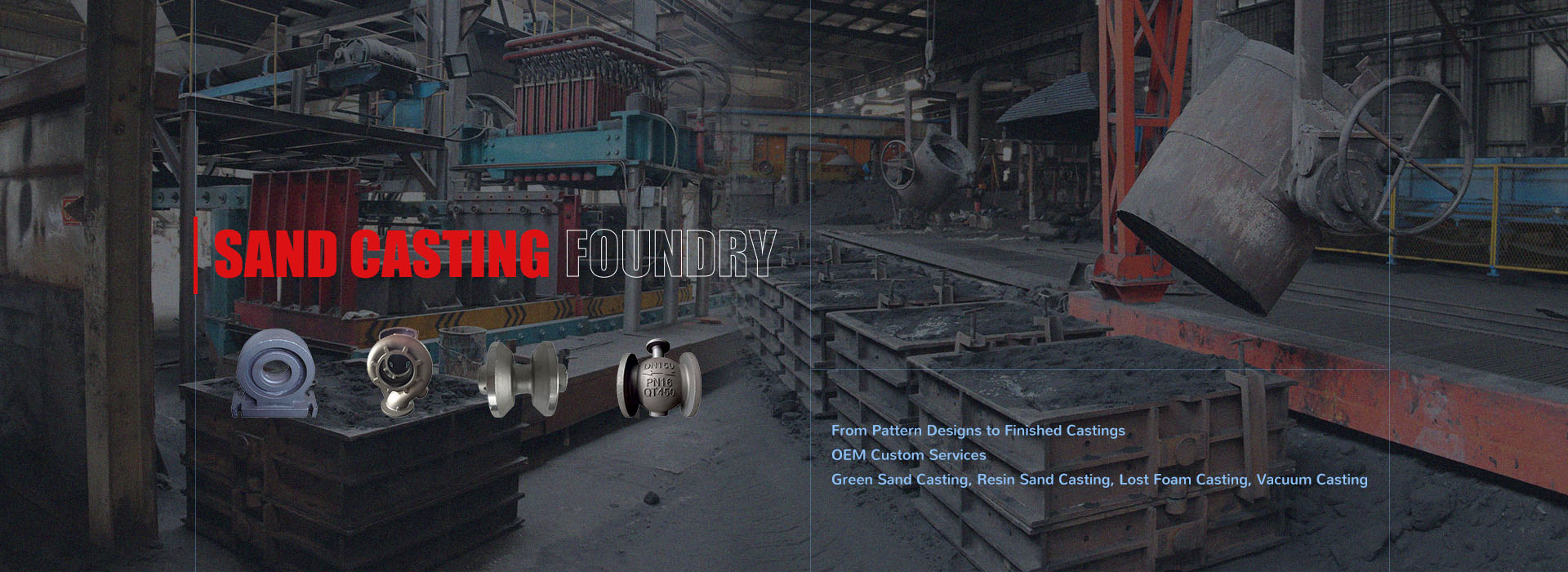

Sand Casting

Sand casting foundry with OEM custom services to cast metals including gray cast iron, ductile cast iron, cast steels, stainless steel, aluminium alloys, brass, bronze, nickel and cobalt alloys.more -

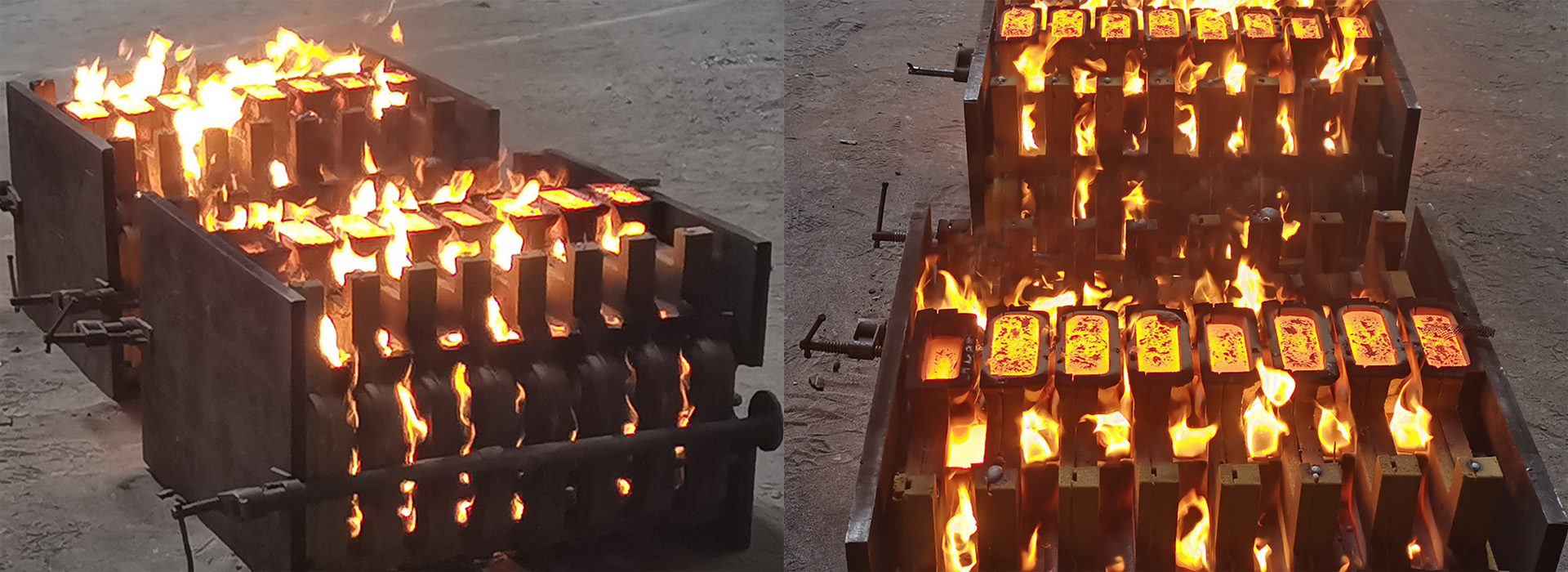

Shell Mould Casting

Resin pre-coated sand shell mold castings with wide range of molten metals and alloys of ferrous and non-ferrous. No-bake shell mould casting process is also available.more -

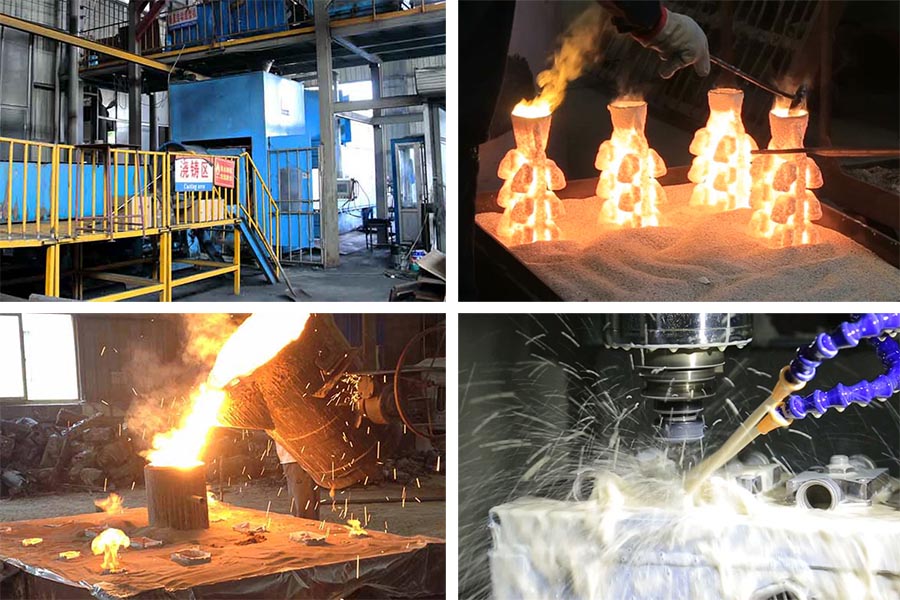

Lost Foam Casting

Cast steel and cast iron lost foam casting foundry in China with CNC machining, heat treatment and surface treatment services. Heavy duty truck casting and machining spare parts.more -

Vacuum Casting

Vacuum (V process) casting foundry in China with materials of gray cast iron, ductile cast iron, CrMo alloy steel, SiMn alloy steel, brass and other available metals.more -

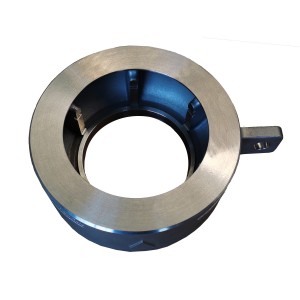

CNC Machining Services

CNC machining company to provide stainless steel machined parts, alloy steel machined parts, carbon steel machined parts, cast iron machined parts, brass & bronze machined parts.more

Rinborn Machinery Co., RMC Foundry, with its official company name Qingdao Rinborn Machinery Co., Ltd, was founded in 1999 by our founding team based in Qingdao, Shangdong, China. We have now grown to become one of the finest metal casting and precision machining companies specializing in lost wax investment casting, sand casting, shell mold casting, lost foam casting, vacuum casting and CNC machining.

With fully organized facilities and rich experience in engineering, manufacturing and quality control, RMC utilizes the new advanced technologies which help us produce complex, high precision, near-net or net shape castings of a diverse range of ferrous metals and non-ferrous metals.

-

AISI 347 Stainless Steel Exhaust Manifold

-

Cast Steel Part from China Foundry

-

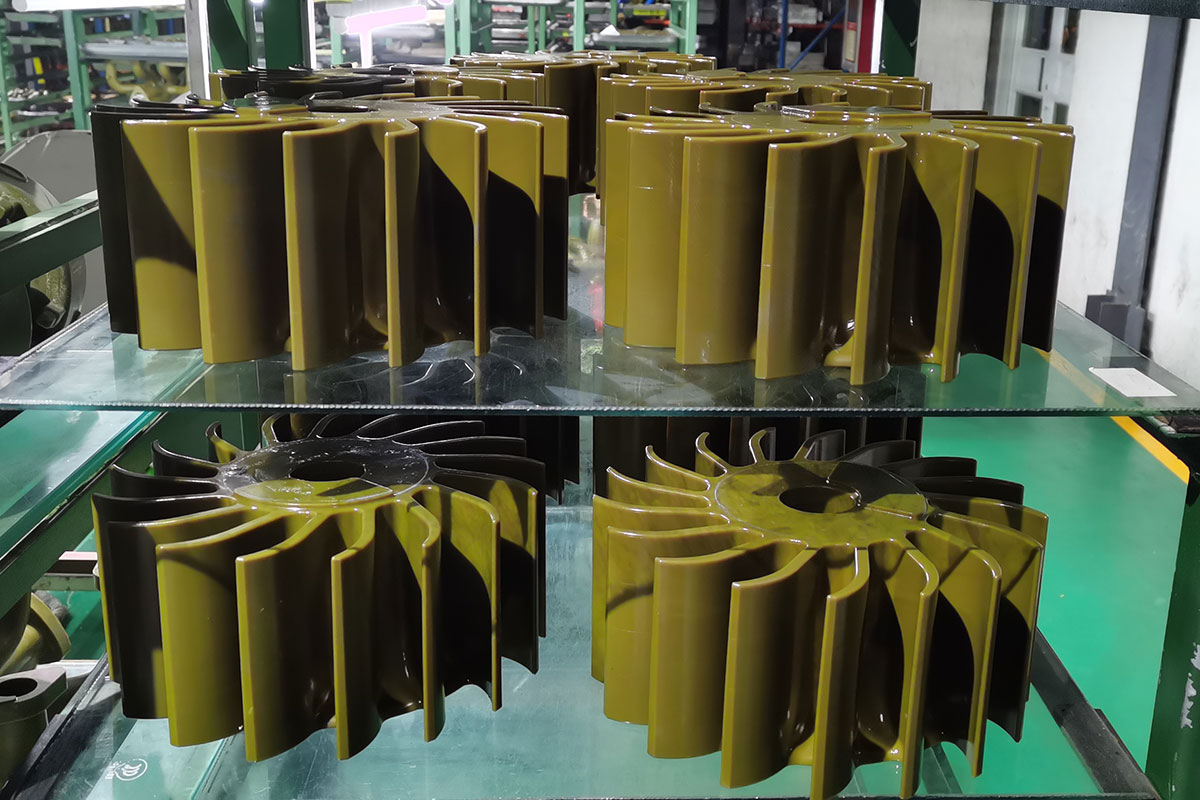

Centrifugal Pump Vane Impeller

-

Low Carbon Steel Casting Part

-

WCB Carbon Steel Casting Product

-

Stainless Steel Centrifugal Pump Closed Impelle...

-

Custom Valve Housing of Cast Duplex Stainless S...

-

Duplex Stainless Steel Precision Investment Cas...

-

Custom Cast Stainless Steel Precision Casting P...

-

Custom Carbon Steel Investment Casting for Truc...

-

Brass Sand Casting Product with CNC Machining

-

Grey Cast Iron Part with Custom Casting Services

-

Cutting Tools25-11-27Cutting processes involve using hard materials to cut soft materials, and pressure-resistant materials to cut brittle materials. Metal materials, depending on their grade,...

-

Analysis and Prevention of Common Casting...25-10-31Cold Shut Causes: The molten metal has a low pouring temperature and poor fluidity; the gating system design is unreasonable — the number of ingates is too small, the cros...

-

Analysis and Prevention of Common Casting...25-10-24There are many types of casting defects. The following mainly introduces the causes and preventive measures of common ones. Blowholes and Pinholes Blowholes can be ...